What is CAD (Computer-Aided Design)? Uses, Benefits, and Software Explained

Computer-Aided Design (CAD) is the use of design software to help create and view product designs more easily. It is used by engineers, architects, product designers, and draftsmen to make both 2D drawings and 3D models. CAD helps improve accuracy, supports creativity, and speeds up the design process. Also called Computer-Aided Design and Drafting (CADD), this technology is widely used in manufacturing, construction, automotive, aerospace, and interior design fields. With digital tools and virtual simulations, CAD makes it easier to plan and test ideas before making real products.

What is CAD mainly used for?

CAD software is primarily used for the digital creation of 2D drawings and 3D models, allowing users to visualize physical objects before they are actually manufactured. These digital designs enable teams to analyze, revise, and improve a product’s layout before investing time, labor, materials, or funds in building a physical prototype.

Beyond generating conceptual visualizations and component layouts, CAD systems are also used to:

- Represent elevation views in architectural and engineering contexts.

- Illustrate how different system components function together.

- Identify areas that may require inspection or improvement.

- Conduct strength, stress, or motion analysis for mechanical assemblies.

- Define or refine a component’s manufacturing processes.

- Automatically generate a bill of materials (BOM).

- Simplify component creation through CNC (Computer Numerical Control) manufacturing workflows.

Benefits of CAD

CAD eliminates the traditional reliance on pen-and-paper drafting for engineers, architects, and design professionals. By using computer systems, the entire design process is streamlined—resulting in faster workflows and increased productivity. CAD also enhances design precision and simulates real-world functionality better than manual sketches.

Another key advantage of CAD is improved project documentation and communication. CAD systems include annotations that specify materials, manufacturing steps, dimensions, tolerances, and interaction points. This helps teams collaborate effectively and ensures a smoother design-to-production pipeline.

Additionally, CAD contributes to a centralized manufacturing design database, which helps in:

- Creating highly accurate and innovative designs.

- Reducing material waste and production costs.

- Speeding up development cycles and time to market.

- Enhancing the final product’s overall quality.

Some standout advantages of CAD over traditional drafting include:

- Reduced costs for design development.

- Accelerated timelines due to streamlined design workflows.

- Easy modifications without the need to redraw entire designs.

- Improved design quality with embedded data like angles, presets, and dimensions.

- Enhanced legibility and consistency, supporting easier interpretation by collaborators.

- Easy sharing and collaboration through standardized digital files.

- Support for advanced features like solid modeling, generative design, and parametric adjustments.

CAD Software Output

Who Uses CAD?

CAD usage varies depending on the industry and professional role. Below are some of the key professionals and industries that rely on CAD tools:

- Architects

- Engineers (Aerospace, Civil, Transportation, etc.)

- City Planners

- Graphic Designers

- Animation Illustrators

- Drafters

- Fashion Designers

- Interior Designers

- Exterior Designers

- Game Designers

- Product Designers

- Industrial Designers

- Manufacturers

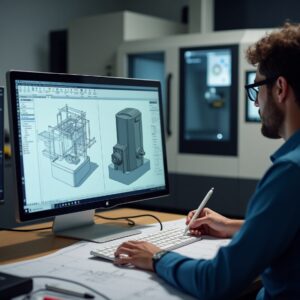

Computer-aided design models—such as the schematic image on the right—and photorealistic renderings—like the one on the left—are both powerful tools that help creators visualize complex ideas in three dimensions.

CAD Software and Tools

A variety of CAD (Computer-Aided Design) tools are available to assist designers, engineers, and manufacturers in product development, 3D modeling, and simulation processes. These tools generally fall into one of three primary categories:

2D CAD. This software creates two-dimensional geometric shapes such as lines, rectangles, circles, and polygons to visually represent designs. Most 2D CAD solutions feature a built-in library of predefined shapes, hatch patterns, and the ability to auto-generate a Bill of Materials (BOM) for streamlined drafting and documentation.

2.5D CAD. Commonly used in CNC (Computer Numerical Control) machining environments, 2.5D CAD software simplifies component fabrication by producing contour maps and visualizing depth information—functionalities that standard 2D CAD tools cannot provide.

3D CAD. These applications are ideal for complex engineering projects that require photorealistic models to simulate, visualize, and optimize a final product before mass production. 3D CAD enhances collaboration, helps catch design flaws early, and supports digital twin technology.

Many CAD solutions are engineered to meet specific industry needs—ranging from industrial design and automotive engineering to civil architecture and aerospace. Others offer cross-functional capabilities suitable for diverse sectors. Some of the most widely used CAD platforms include:

- 3D CAD by SolidWorks

- Altium Designer by Altium

- AutoCAD by Autodesk

- CATIA by Dassault Systèmes

- IronCAD Design Collaboration Suite by IronCAD

- LibreCAD (open-source)

- MicroStation by Bentley Systems

- Onshape

- OpenSCAD (open-source)

- Solid Edge by Siemens

When selecting a CAD solution, organizations should first identify their technical requirements and project goals. Next, they must evaluate each software product’s core features, system compatibility, and interoperability—especially concerning file format standards used in their design and engineering ecosystems. Equally important is choosing a vendor that offers comprehensive customer support, technical training, and up-to-date documentation.

CAD and CAM

CAD is frequently integrated with CAM (Computer-Aided Manufacturing) in modern digital production environments. CAD/CAM software is essential in the creation of electronic products, circuit board layouts, mechanical parts, and more. However, while complementary, CAD and CAM are distinct in purpose and function.

CAD involves the creation of two-dimensional or three-dimensional digital prototypes that replicate real-world components. Using CAD tools, engineers, architects, and drafters generate precise vector-based drawings, simulations, and renders that represent the conceptual design phase.

CAM software takes these CAD models and converts them into executable code—typically G-code—used by machines to automate the production process. This code translates the digital blueprint into physical output through machining operations such as cutting, drilling, milling, lathing, and grinding.

Conclusion

CAD has transformed the way industries visualize, design, and manufacture products. With its advanced capabilities in 2D drafting, 3D modeling, and simulation, CAD software accelerates workflows, reduces errors, and enhances collaboration across design teams. From architecture and mechanical engineering to electronics and fashion design, Computer-Aided Design is essential for modern product development and digital manufacturing.

As technology continues to evolve, integrating CAD with CAM and other digital tools will unlock even greater innovation. Choosing the right CAD software—tailored to your industry needs and compatible with your workflow—can significantly improve your productivity and product quality. Whether you’re a student, startup, or established enterprise, adopting CAD is no longer optional – it’s a competitive necessity.

Add a comment